Nara Case Study

Overview

Recognizing an opportunity to innovate, we took on an internal project to completely reimagine the hospital bassinet. This led to the creation of the Nara Bassinet, where we leveraged all our capabilities to design and manufacture a beautifully crafted, safe, and ergonomic care solution that brings mothers closer to their newborns.

Tekna

Medical Device

Good Design® Award

Core77 Community Choice Prize

Core77 Notable Award

The Challenge

The hospital bassinet market had been largely overlooked for decades, resulting in designs that were essentially “filing cabinets on wheels.” They were bulky, difficult to clean, and inaccessible. Nurses in the NICU and mother/baby units expressed frustration with the clunky nature of existing bassinets, citing issues with stooping, straining, and inefficient maneuvering. New mothers also struggled to comfortably reach their babies from their beds. It became clear there was a significant need for an innovative, user-centric solution.

The Product

Our solution was the Nara Bassinet, developed through a holistic and iterative process that integrated our various disciplines. We started by gathering qualitative data through one-on-one user interviews and focus group discussions with NICU and mother/baby nurses, as well as hospital environmental services staff. We observed their daily interactions and documented pain points like bulkiness and inaccessibility. We also gathered insights from new mothers about their challenges reaching their newborns. This research identified critical unmet needs and shaped our design objectives.

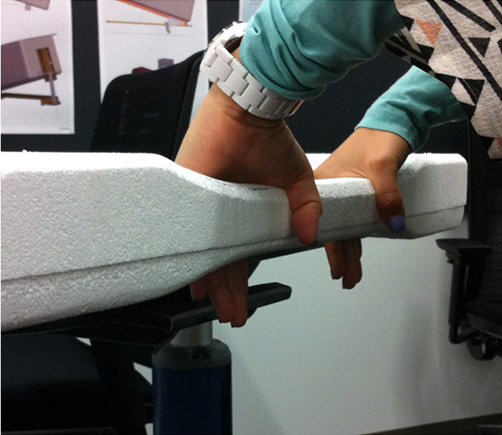

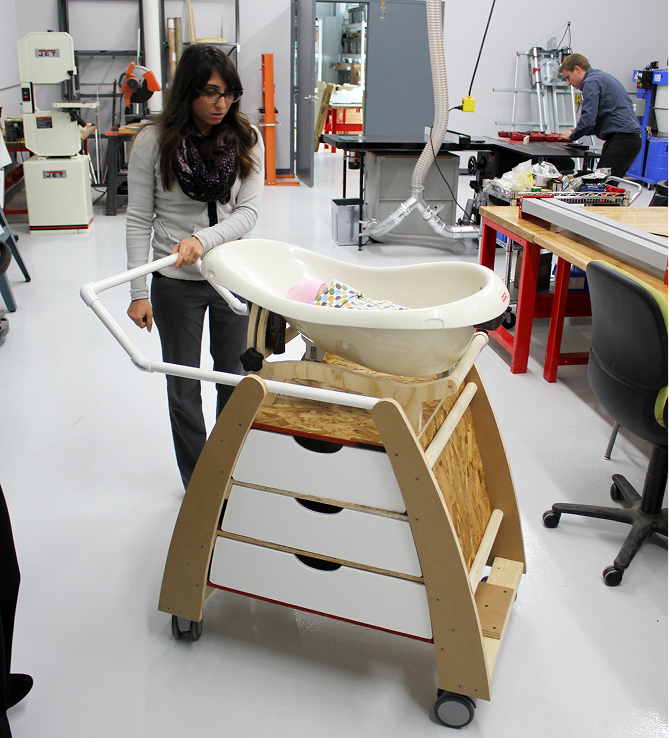

Leveraging our research, our human factors specialists focused on optimizing user interaction. We analyzed user postures, movements, and cognitive load during tasks like maneuvering the bassinet and accessing the infant. This analysis directly informed design decisions to minimize caregiver strain, ensure quiet and efficient movement, and make it effortless for mothers to reach their babies. Full-scale mockups and comprehensive usability testing with diverse user groups validated the design’s effectiveness.

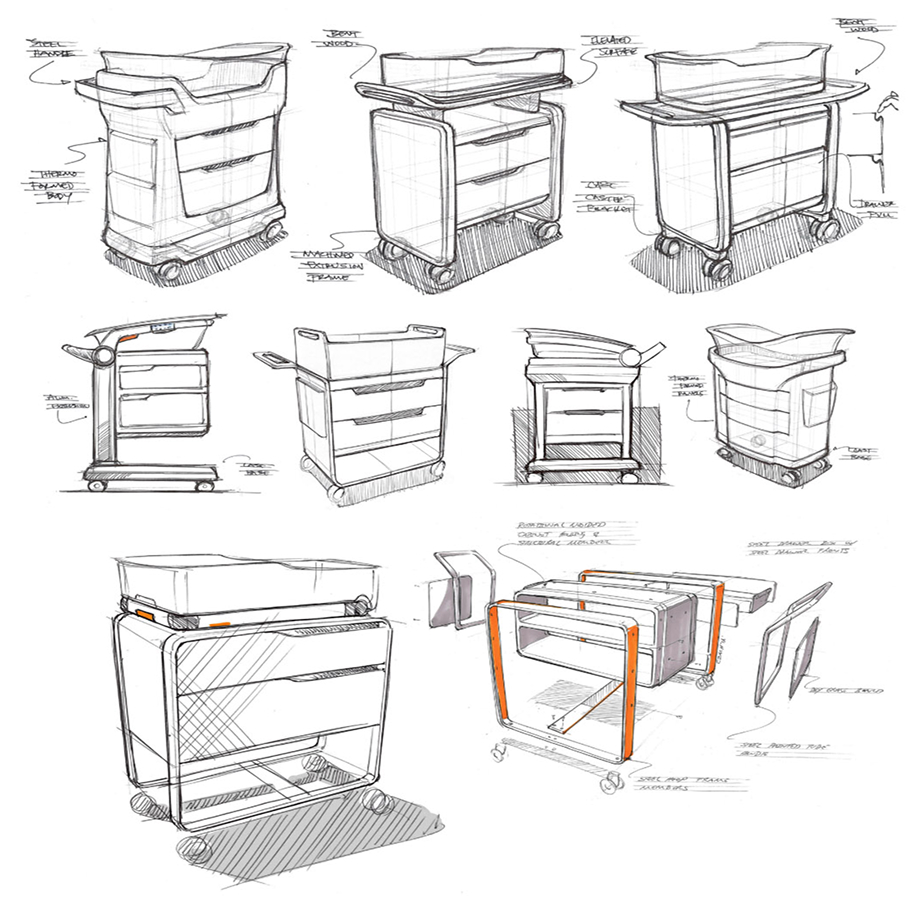

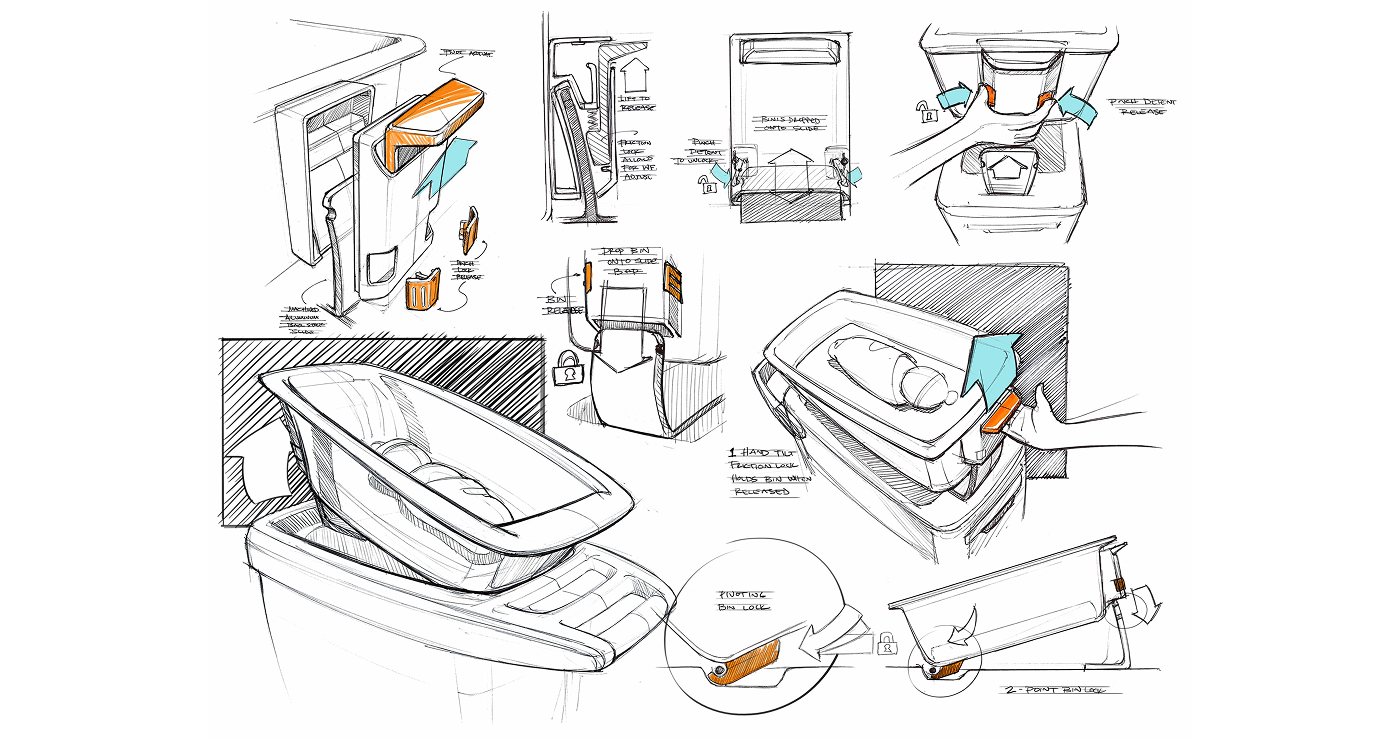

Our industrial design team translated research and human factors insights into a visually appealing and highly functional form. We began with extensive sketch exploration, then moved to detailed CAD development. In-house 3D printing and various fabrication methods facilitated rapid prototyping. This iterative process allowed us to quickly test and refine the aesthetic and functionality, ensuring the bassinet was not just beautiful but also intuitive and practical for daily hospital use, moving beyond the “filing cabinet” aesthetic.

As the product evolved, so did its distinct brand identity. We recognized the need for a compassionate and innovative brand in healthcare. Our branding efforts included a comprehensive strategy emphasizing approachability and an inviting presence. We created all print materials and developed engaging animation and video content to showcase the bassinet’s features. The name “Nara” was carefully selected to capture the essence of the reinvented experience.

Our engineering team ensured the Nara Bassinet’s safety, durability, and compliance as a Class II medical device through robust mechanical engineering. This involved meticulous design for manufacturing and assembly (DFM/DFA), material selection, and structural analysis. They collaborated closely with industrial design to translate aesthetic vision into technically sound, manufacturable components, and provided critical regulatory support to meet all necessary healthcare industry standards.

After successful design validation, we managed the transition to full-scale production. An initial pilot production run supported early market access and limited clinical use, allowing for real-world feedback and refinement. We then scaled manufacturing to exceed our MedTech OEM customer’s sales projections for four consecutive years. To maintain quality and regulatory controls, we developed robust documentation, tooling, and assembly protocols, facilitating a seamless transition of manufacturing operations to the OEM’s facility. This ensured design intent was preserved, delivering a locally designed and manufactured solution backed by a predominantly Michigan-based supply chain, successfully bridging innovation to commercialization at scale.

1. Narrow cabinet design

Allows the bassinet to be positioned very close to the mother’s bedside, facilitating easy interaction and bonding

2. Three points of contact

This secure fastening method significantly reduces the risk of tipping, a common safety concern with traditional bassinets

3. cart wheel design

Steel-locking, soft wheel casters provide a smooth, quiet ride for the infant during transport and offer excellent stability when stationary.

4. Height adjustable

Optimizes caregiver ergonomics and allows it to be lowered for easier maternal interaction, particularly for mothers recovering from C-sections.

The results

The Nara Bassinet received overwhelmingly positive responses during testing, validating its final design and innovative features. It garnered significant industry recognition, including a A Good Design® Award, the Core77 Community Choice Prize, and a 2017 Core77 Notable Award.

Our thoughtful approach to product introduction laid the groundwork for a full production ramp-up. We successfully scaled manufacturing to meet and exceed the MedTech OEM customer’s sales projections for four consecutive years. To maintain quality and regulatory controls, we developed robust documentation, tooling, and assembly protocols, facilitating a seamless transition of manufacturing operations to the OEM’s facility. This ensured that the design intent was preserved, delivering a locally designed and manufactured solution backed by a predominantly Michigan-based supply chain, successfully bridging innovation to commercialization at scale.

Infants held per year

Units manufactured

Components per assembly

of nurses say Nära allows them to provide better overall patient care

Recent Work